LEARNING WHENEVER AND WHEREVER YOU WANT

To complement our open seminars and in-house training programs, we offer have put together an e-learning program that includes web-based training and learning nuggets as part of our blended learning approach.

While gradually expanding our current portfolio, we will also be developing personalized digital learning elements to meet your specific needs. Find an overview of this product in our Learning Management System.

Use our web-based training sessions to learn online whenever, wherever and as often as you like! Acquire, refresh or expand your knowledge about Lean in compact learning modules. Our learning nuggets enable you to integrate learning into your day-to-day work easily and flexibly with short, digital units.

Marianne Zaiser

Project Manager Virtual Learning Solutions

Phone: +49 7024 8056 191

E-Mail: marianne.zaiser@staufen.ag

Your benefits at a glance

Highly flexible

Personalized learning

Long-term learning success

Time savings

WEB-BASED TRAINING – LEARNING WITHOUT THE TIME PRESSURE

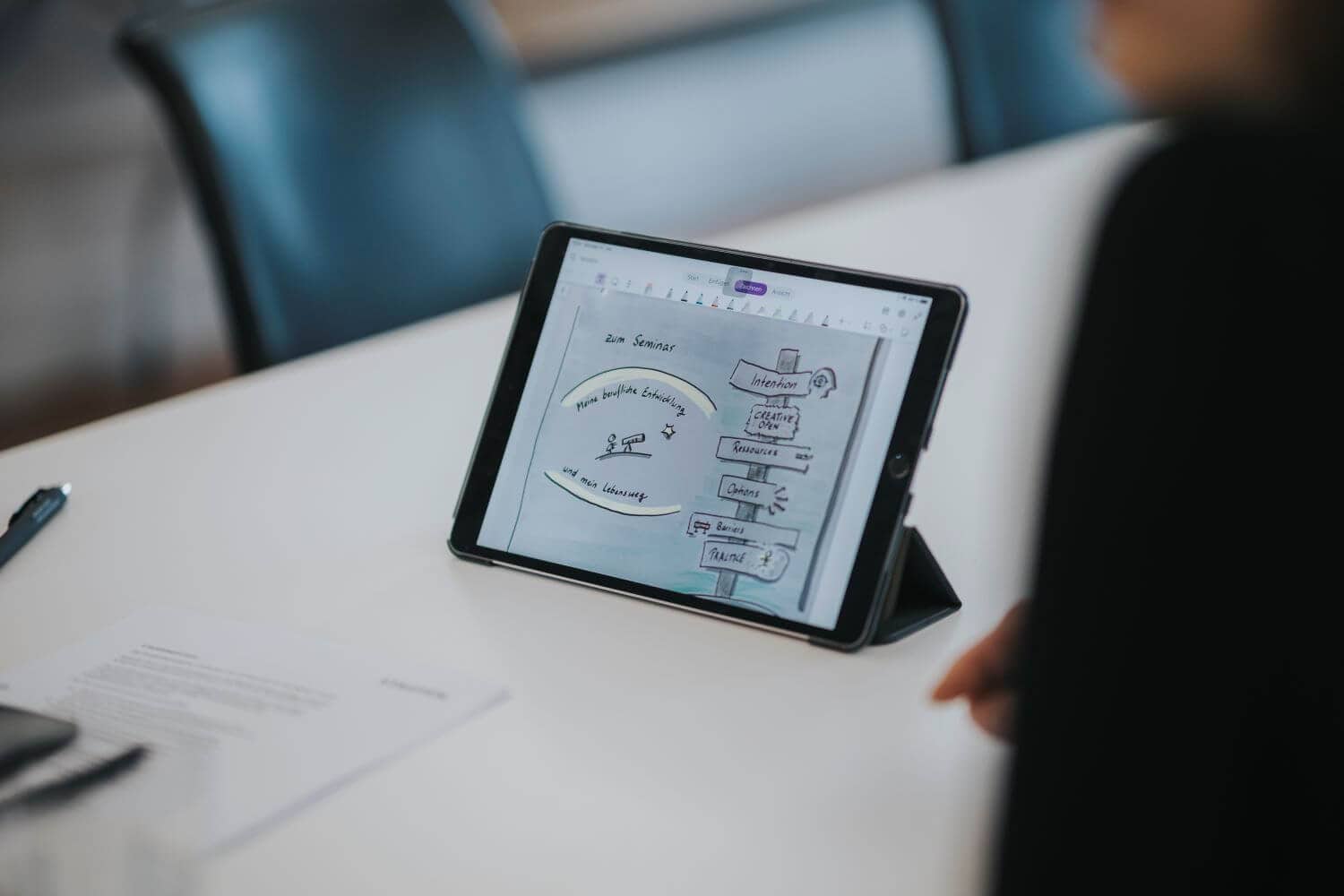

Our web-based training sessions provide you with flexible training in the form of compact online learning modules (approx. 60 minutes). Skip any modules that have already learned and mastered or repeat any modules that require in-depth learning. Practical exercises and tests help you to review and solidify the knowledge you’ve acquired.

Principles of Lean Management

Professionally Structure Workshops

Give Feedback – Accept Feedback

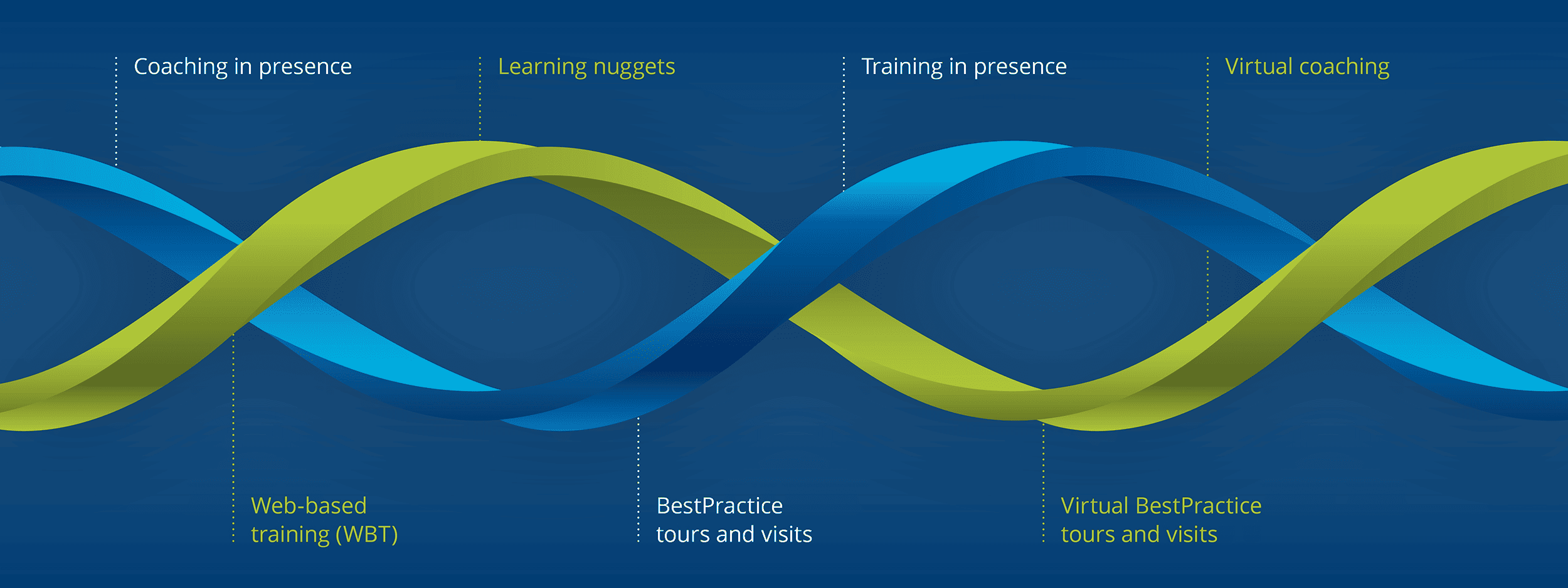

BLENDED LEARNING APPROACH – IN-PERSON MEETS VIRTUAL

The blended learning journeys of our training programs consist of in-person and virtual learning elements offering the best of both worlds.

Because: new work worlds require new learning! We firmly believe that blended learning, meaning a combination of digital and analog learning elements, will be an established part of learning in the future.

Each element, whether digital or analog, is instrumental in achieving the learning objectives and in turn the effectiveness of the training and development. So, our digital elements are not only used as an add-on.

Do you have questions? Get in touch with us!

We would be happy to consult with you about your specific blended-learning journey. We look forward to speaking with you in person and working with you.

Marianne Zaiser

Project Manager Virtual Learning Solutions

Phone: +49 7024 8056 191

E-Mail: marianne.zaiser@staufen.ag